It is a package whose shape can be adjusted. It is because of this property that it is suitable for packaging various products. We also advise you on choosing the right printing technology that is right for your products.

Digital printing: The key advantage is that we do not need to make printing clichés for the printing itself, and the printing technology itself is more flexible and has a shorter print preparation. Due to the above, the technology is more suitable for smaller series of products.

Flexo printing: For printing we need the production of printing plates – clichés. The printing technique is suitable for printing medium to large quantities with quality results. The technique also allows flexibility in the layout of the designs, and in most cases it is an economical printing technology.

Gravure printing: For printing we need the production of printing cylinders – cylinders. The printing technique is suitable for large quantities with superior printing results, which also enables the printing of additional applications – soft touch, paper touch, etc.

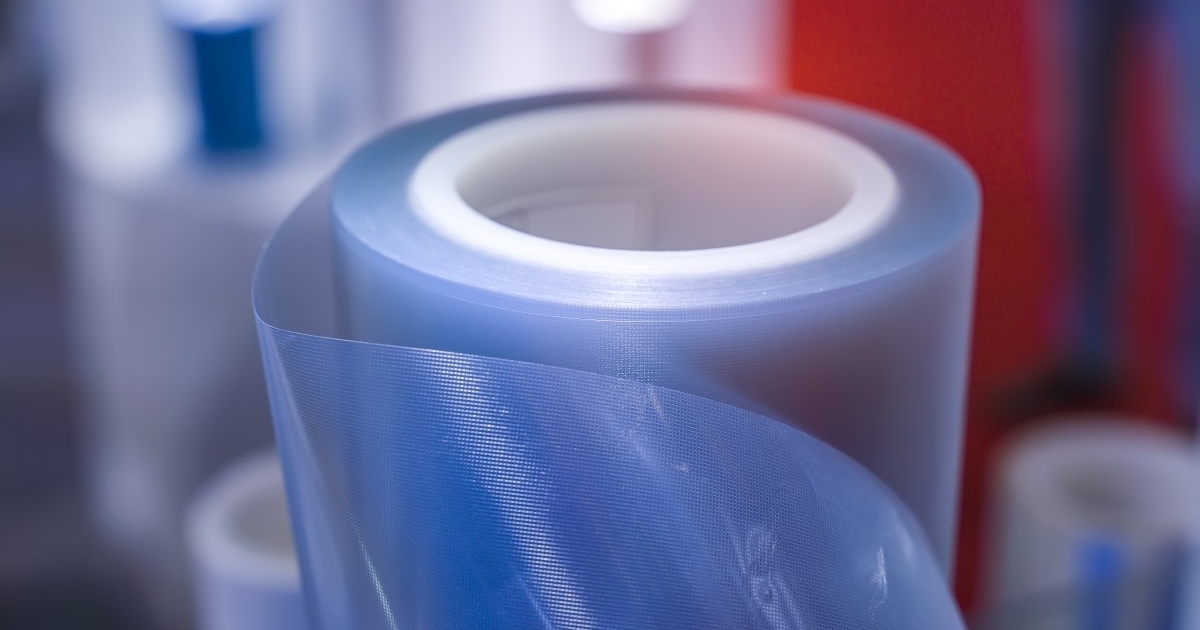

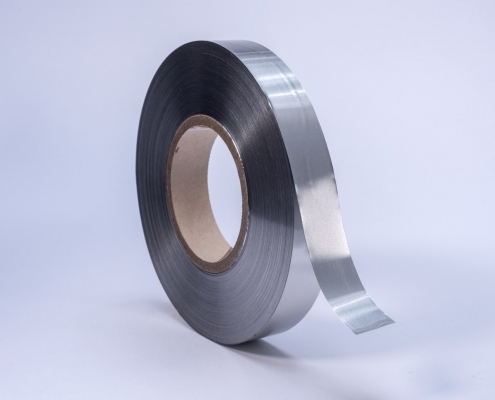

Packaging can be divided according to the composition itself, which depends on the purpose of packaging, the necessary product protection and marketing presentation of products:

- single-layer foils (intended for basic packaging of simple products)

- two-layer foils (intended for packaging fresh and frozen products, the possibility of extending the shelf life of products)

- multilayer foils (intended for packaging demanding products with an emphasis on barriers – passage of light, air and leakage of gases or aromas)

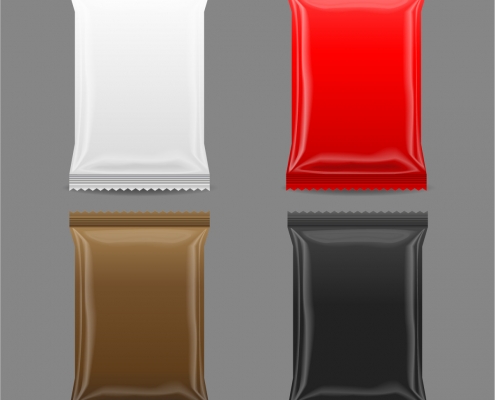

- bags (intended for the packaging of small batches of products or the packaging of promotional products)

Great emphasis is placed on packaging that is recyclable.

Flexible packaging extends the life of packaged products, so it is usually used for packaging products such as:

- snacks (single-layer or multi-layer materials are used, depending on the required barrier of the packaged product)

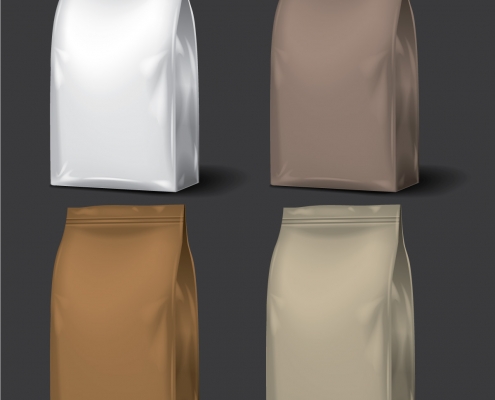

- coffee (coffee beans, ground coffee, capsules and instant coffee beans require a high barrier to moisture, oxygen and light, while maintaining the aroma is paramount)

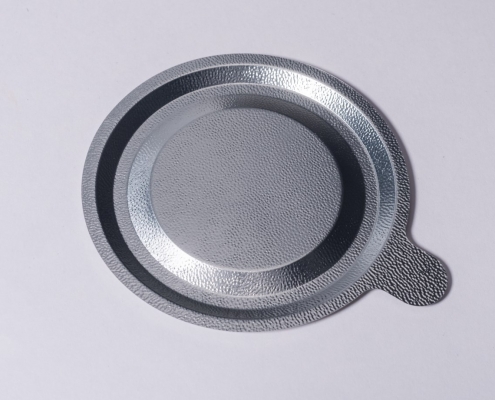

- dairy and meat products (for this very sensitive product category we suggest flexible packaging materials that ensure airtight sealing of the weld, low permeability to gases / moisture, transparency / high strength, mechanical resistance and maintaining the integrity of the product)

- frozen products (we suggest packaging materials that are suitable for mechanical resistance, usability and exceptional print quality; for frozen vegetables, low light transmittance is crucial in protecting the product)

- animal nutrition (we offer solutions that ensure the preservation of freshness and taste in combination with the use of two-layer or multi-layer foil)

- special products (to preserve flavors, aromas and consistency in dry nuts, dehydrated food and beverages, sauces, ready meals, spices, condiments and food additives, the use of highly barrier laminates is required)